Introduction

Streetlight poles are essential urban infrastructure components, providing illumination to roads, streets, and public spaces. These poles are constantly exposed to harsh environmental conditions, including rain, wind, sunlight, and pollutants, which can cause deterioration over time. To enhance the durability and lifespan of streetlight poles, two critical processes are commonly employed: galvanization and powder coating. This article explores the significance of these processes, their applications, and the benefits they offer.

Main Content

1. Definition and Purpose of Galvanization and Powder Coating

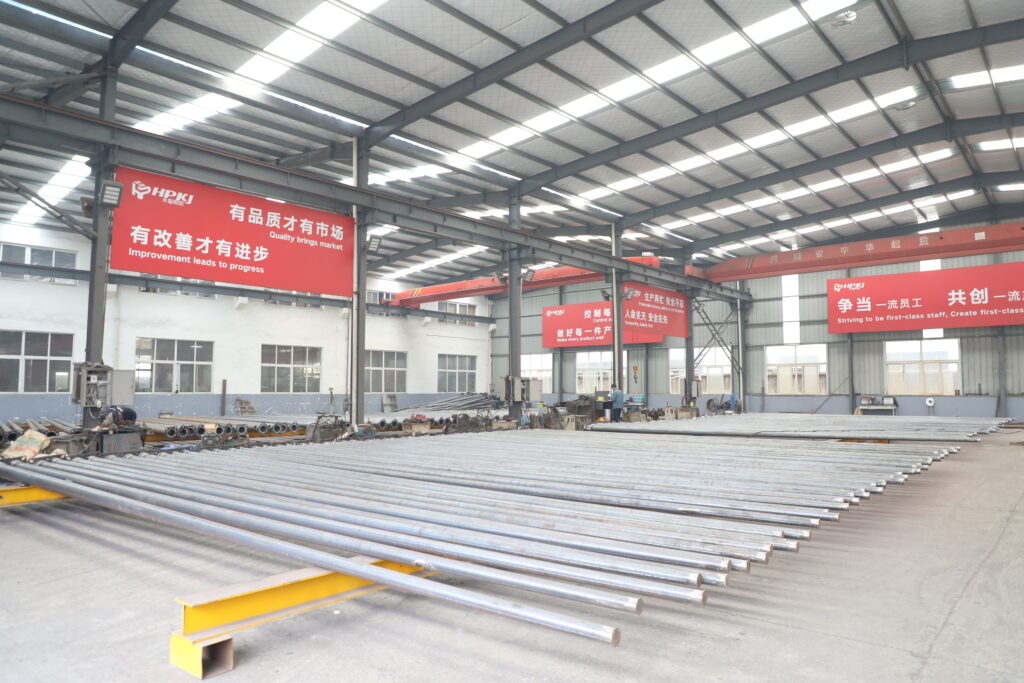

Galvanization is a process in which a protective zinc coating is applied to steel or iron to prevent rusting. This process is typically achieved through hot-dip galvanization, where the metal is submerged in molten zinc, creating a robust and durable coating that adheres to the surface. The primary purpose of galvanization is to provide long-term corrosion protection, especially in environments where the poles are exposed to moisture and other corrosive elements.

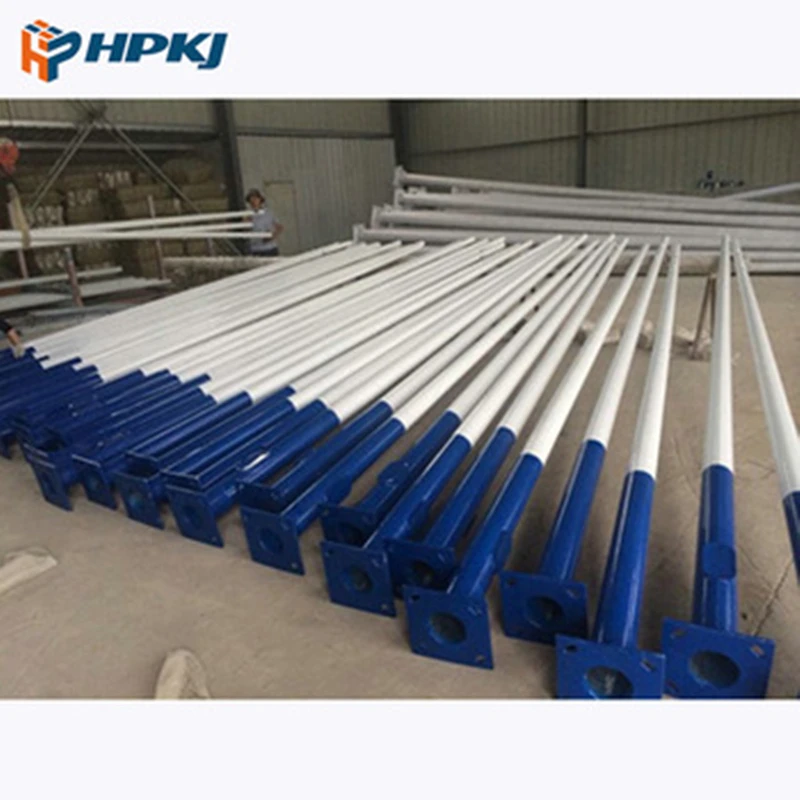

Powder Coating is a finishing process that involves applying a dry powder to a metal surface, which is then cured under heat to form a solid, smooth, and uniform coating. This coating serves as an additional protective layer, enhancing the aesthetic appeal of the streetlight poles and offering resistance against chipping, scratching, and fading.

2. Classification of Galvanization and Powder Coating Processes

a. Types of Galvanization

- Hot-Dip Galvanization: The most common method, where streetlight poles are dipped into a bath of molten zinc. This method provides comprehensive coverage and excellent protection against corrosion.

- Electro-Galvanization: Involves applying zinc through an electroplating process. Although it provides a thinner coating compared to hot-dip galvanization, it offers good protection for indoor or less harsh environments.

b. Types of Powder Coating

- Thermoset Powder Coating: Utilizes thermosetting resins, which, when cured under heat, create a strong, durable finish. This type of coating is ideal for streetlight poles as it offers excellent weather resistance.

- Thermoplastic Powder Coating: Melts and flows when exposed to heat and solidifies upon cooling. This type is known for its toughness and is often used for applications requiring a thicker coating.

3. Materials Used in Galvanization and Powder Coating

Materials for Galvanization:

- Zinc: The primary material used in galvanization due to its excellent corrosion resistance and ability to form a strong bond with steel or iron surfaces.

- Steel/Iron: The base materials for streetlight poles, chosen for their strength and durability. These metals are prone to rust without proper protection, making galvanization essential.

Materials for Powder Coating:

- Epoxy: Known for its strong adhesion properties and chemical resistance, epoxy is often used for powder coating streetlight poles in industrial or coastal environments.

- Polyester: Offers superior UV resistance and is widely used for outdoor applications, making it a popular choice for streetlight poles.

- Polyurethane: Combines the benefits of epoxy and polyester, providing excellent weatherability and resistance to chemicals and abrasion.

4. Benefits of Galvanization and Powder Coating

a. Corrosion Protection The primary benefit of both galvanization and powder coating is their ability to protect streetlight poles from corrosion. Galvanization provides a sacrificial layer of zinc, which corrodes instead of the underlying metal, thus extending the lifespan of the pole. Powder coating adds an extra layer of protection, sealing the surface and preventing moisture and contaminants from reaching the metal.

b. Enhanced Durability The combination of galvanization and powder coating significantly increases the durability of streetlight poles. Galvanized poles are less prone to rust and can withstand harsh environmental conditions, while powder-coated poles resist chipping, scratching, and fading, ensuring they maintain their appearance and functionality over time.

c. Aesthetic Appeal Powder coating allows for a wide range of color options and finishes, enabling customization of streetlight poles to match the aesthetic requirements of different urban settings. This not only enhances the visual appeal of the poles but also contributes to the overall beauty of the urban landscape.

d. Cost-Effectiveness While the initial cost of galvanization and powder coating may be higher than other methods, the long-term benefits outweigh the expenses. The extended lifespan and reduced maintenance requirements of treated streetlight poles lead to lower overall costs in the long run.

5. Conclusion

The importance of galvanization and powder coating in the production and maintenance of streetlight poles cannot be overstated. These processes provide critical protection against corrosion, enhance the durability and longevity of the poles, and offer aesthetic benefits that contribute to the urban environment. By investing in high-quality galvanization and powder coating, municipalities and urban planners can ensure that streetlight poles remain functional and visually appealing for many years.

In summary, galvanization and powder coating are essential processes in the production of streetlight poles, offering protection against corrosion, enhancing durability, and providing aesthetic customization options. The use of these processes not only extends the lifespan of the poles but also contributes to the overall efficiency and beauty of urban infrastructure. By understanding the importance and benefits of galvanization and powder coating, stakeholders can make informed decisions to ensure the longevity and effectiveness of streetlight poles in their communities.